How to Make Invention Prototypes, Find Prototyping Companies and Get Help.

Click on the button below for a free consultation.

Continue reading to learn details about the different kinds of prototypes and prototyping processes.

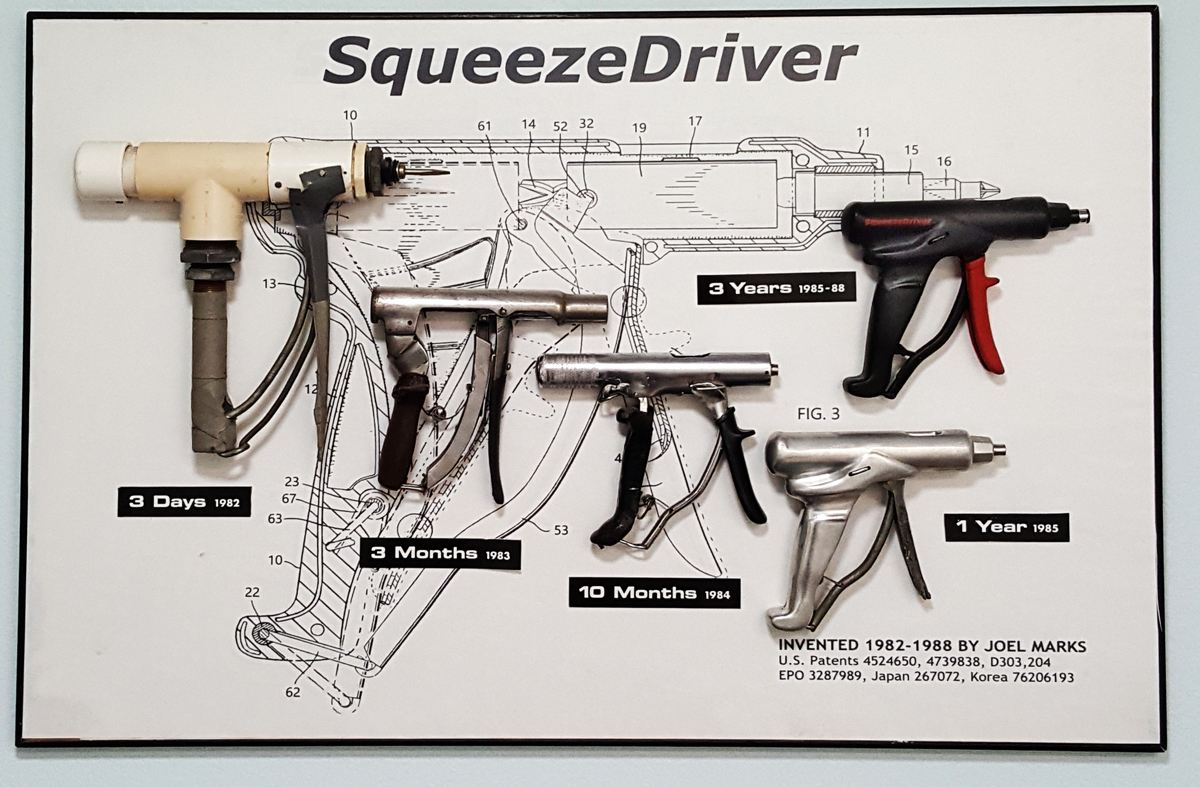

Prototypes serve different needs and costs vary tremendously depending on the kind of prototype you choose. As a first step we strongly recommend that every inventor try to make a rough prototype on their own. In many cases you can make a rough prototype yourself for next to nothing. 3D images and simple animation are affordable for most inventors and a good way to visualize an idea and conduct market research. Virtual (CAD) and working prototypes can be expensive but are important steps to turn your idea into a manufactured product. When you build a working prototype you will often discover features that can be patented.

Introduction to Prototyping

What is a prototype?

A prototype is a virtual or real model of your invention, something that enables a user or developer to imagine or experience how the invention works. It could be an artistic 3D image, software, engineered CAD model or an actual physical device. It might made of taped cardboard or 3D parts that have been carefully designed and “printed” on a rapid prototyping machine.

Why do I need prototypes of my invention idea?

A prototype is the first step of taking the idea in your head and turning it into an actual product. Before investing deeply in patents, final engineering and tooling for manufacturing you can confirm both the market potential and whether or not your design idea will work the way you want it to. You can get the feedback you need to create a successful product. Building a prototype is an essential step in the inventing process and until you have actually built at least a rough prototype that can be tested you will be clueless about the true merits of your invention. You need to show a prototype to your target customers to confirm your intuition that people want to buy your invention idea.

How will a prototype help the invention process?

A prototype enables you to receive user input, perfect your design and possibly create new patentable features. It is virtually impossible to begin a conversation with a potential licensee unless you have something to show. Showing a prototype enables you to get critical feedback.

What is the process for prototyping my invention idea?

Generally you'll build several prototypes. The crude prototype is a model that enables you to get a better feel for the basic premise of your invention. A working prototype is something that allows users to try out some or all of the features of the invention. A final prototype is a model that looks and functions almost like a manufactured product. 3D images are great for getting market feedback. Engineered CAD models are necessary to communicate with suppliers and get accurate quotes on manufacturing.

Costs

Costs can vary by 10X or more depending on many factors, but for a rough understanding, the typical costs for prototypes of relatively simple mechanical products are:

- Rough Prototype: $5 if you make yourself using scrap materials

- Photo Realistic Illustrations: $400-$1500

- 3d Animation: $700-$3000

- Working Demonstration and Evaluation Prototype: $2,500 - $15,000+

- Functional Industrial Designed Working Prototype: $15,000 - $50,000++

What is a good first step in prototyping my invention idea?

3D photo realistic images are a great way to bring your vision to life. Images supported with text closely track the way real world buyers experience new products and are fantastic for market research and presentations to prospective partners, investors and licensees. They are also far less expensive than working models or models that have been engineered for manufacturing. For these reasons we recommend them as an early step in the invention development process.

What is the difference between a 3D (CAD or CAM) model and a 3D image or rendering?

Avoid Confusion: Some companies use the term “3D model” very loosely and inventors who buy concept images from such providers sometimes believe their inventions are ready for manufacturing. That is not the case unless engineering has been completed - usually an expensive step. The 3D photo realistic image service offered by Invention City is intended for affordable conceptualization and market research. 3D CAD or 3D CAM models (Computer Aided Design or Manufacturing) are engineered for function or manufacturing; they are a different (and more expensive) service. While a 3D CAD model will produce a fine image of the product itself, it will not provide context, like a room, landscape or user.

How can Invention City help me build a prototype of my invention idea?

Invention City will guide you in making the right choices for prototyping your invention. Invention City works with you to translate the image in your mind into one that can be viewed on a computer screen, printed onto paper or developed into a working product by one of our associates. Our illustrators are located in the USA and work under our Confidentiality Agreement. For working prototypes and industrial design, we offer references to the same resources we use ourselves and help you with every step to find the lowest cost and most effective ways to move your project forward. Fill out our referral form HERE.

What is a crude prototype and how do I make one?

The crude prototype is a model that enables you to get a better feel for the basic premise of your invention. For as little money as possible, you should build a crude prototype on your own to help you gain a better understanding of your invention.

Steps for making a crude prototype:

Write a description of what the invention will do.

Make a list of the most important features of your invention.

Draw a picture of what your invention will look like.

Build a model of your invention any way you can (on the cheap)

Think about products that do similar things and items that have a similar look. Walk the aisles of hardware stores, mass merchants etc. Look for items that incorporate one or more aspects of your invention. Go to arts and craft and hobby stores to find materials. If you need specialty materials or parts you'll have a good chance of finding them online at McMaster-Carr (www.mcmaster.com). McMaster-Carr is an amazing resource.

It doesn't matter what materials you use. You can build the prototype with cardboard, duct tape and bailing wire. You can cut up parts from existing products and glue them together.

The crude prototype does not need to be a working model. Its purpose is simply to help you think deeply about your invention and how it will function. This is not a beauty contest. Ugly is ok.

If there is no way for you to build even a crude prototype then you should do your best to draw detailed pictures and write an extensive description of your invention. Pretend the invention exists and write an instruction manual for it. Describe how someone will use it. Include pictures whenever possible. Don't worry if you can't draw well.

Once you've gone through this exercise the odds are good that you'll think of a number of ways to improve your invention. Be sure to keep a record of everything you're doing in your inventor's journal.

What is a working prototype and how do I make one?

As the name implies a working prototype actually works. A user can turn its knobs, squeeze its handles and so on. The working prototype doesn't need to perform as well as a production product – however, it should be able to perform some real world functions. This prototype will help you further improve the design of the invention. Even more important, you can use a working prototype in surveys to confirm the market.

You may need help in building a working prototype. Finding the right kind of help (inexpensive and good) requires a little creative thinking. What kinds of technologies and materials does your working prototype require? These technologies and materials do not need to be the same as those that will be used in the final product. For example, wood or metal or fiberglass or cloth can substitute for different kinds of plastic. A hard-wired actuation switch might be used to represent a wireless one.

Now consider the kinds of people and businesses that work with the materials and technologies your working prototype will require.

Ask friends, family and acquaintances if they know anyone who could build a working model of something like a _________. The something you name should use the same materials and technology as your invention. If your invention is a cordless radial saw you might say, "something like a cordless drill." The term "cordless drill" is a cover for your real invention, a cordless radial saw.

Using a cover will enable you to talk to a lot of people openly, without the need for confidentiality agreements. Confidentiality agreements slow down the development process tremendously. A good cover will enable you to identify the right sources quickly. Once you've found the right source you should have them sign a confidentiality agreement before discussing the details of your invention.

Ideally you'll find someone who has a lot of technical expertise appropriate to your invention and… enjoys taking on prototyping projects as a sideline. Keep in mind that at this stage you do not need to make something that represents how your invention will actually be made. You simply want something that will come close to working like your invention. Like the crude prototype the working prototype does not need to win a beauty contest.

A good starting place to look for help is with a "pattern maker" or "model maker". Pattern or model makers make prototypes that eventually end up as injection molded or cast parts. Sometimes they'll take on more complex projects. Search for these people in business to business yellow pages or at Thomasnet online. Thomasnet.

If you can't find that special low-cost someone then you'll need to take a more expensive and traditional approach.

Steps for building a working prototype:

Find an engineer/designer with a background in the field of your invention. Thomasnet is a good place to start. Invention City can refer you to industrial designers and prototype makers we use ourselves with this form.

Sign a non-disclosure agreement (“NDA”) and show your crude prototype and other information. Explain that you are not yet looking to have a final design for manufacturing - you only want a working model. Discuss the options of prototyping methods and materials. Get quotes (3 different sources) on how much it will cost for a set of basic drawings you can take to prototype makers. If appropriate the drawings should be in a 2D format (3D drawings cost a lot more). Be very clear that you do not need a final design, simply a working model.

With your drawings in hand go and visit prototype makers. Have the makers sign NDAs before discussing the details of your invention. Again you should try to get 3 quotes whenever possible.

The people you are meeting to develop your working prototype can also help you build a final prototype that's ready for manufacturing. If you're short on cash you should find ways to raise the money to pay for the services you need. Design engineers and prototype makers meet hundreds of inventors each year and every inventor thinks he or she is sitting on a gold mine. Despite your fervent belief that the prototype maker would feel lucky if you offered a piece of the action, the odds are 200:1 that he'll feel just the opposite.

You might also consider working with an industrial designer. Industrial designers are to product design what architects are to buildings. Industrial design is the difference between a Dell PC and an Apple iMac, the difference between a Buick and a Jaguar. An industrial designer can manage the entire development process for you. So why not use one? Money.

Right now you simply need something that will do the job. If you were looking for a car you'd buy a used beat-up one that's advertised as "good transportation".

Industrial design makes a huge difference when your product is being offered to consumers in a retail environment. But at this stage of the game it's overkill, like using a sledgehammer as a fly swatter. With that understood, if you want to find an industrial designer, a good place to start is with "ID" magazine of industrial design (available at most bookstores) and online at IDSA.org. You can also find industrial designers at Thomasnet. If you can't afford to hire others and you can't raise the money, then you'll need to do the job yourself.

Be careful when searching for help using the term "prototype." You will find many services that offer "rapid prototyping." This is not what you want. While rapid prototyping is a very cool technology, it is expensive and unwarranted for most independent inventors. Rapid prototyping takes a 3-dimensional CAD (Computer Aided Design) drawing and turns it into a 3-D part that you can hold in your hands. The cost for a 3-D drawing and part varies a lot on complexity and size and might typically range between $1,500 and $15,000.

Common Prototyping Technologies

Following are descriptions of some common prototyping technologies. Sources for these technologies and services can also be found at www.thomasnet.com.

- Casting: Casting creates a part from a liquid material that subsequently hardens. Casting is done in both plastic and metal. All casting begins with an exact model of the part to be produced.

- Silicone Mold Casting: Silicone rubber is poured over a model and cured. The model is cut out of the hardened silicone rubber, leaving behind an exact impression - a mold. The mold can then be filled with plastic resins or wax to create final plastic parts or wax forms for investment casting. Model makers and pattern makers make silicone molds.

- Investment Casting: A wax form is covered in plaster. The wax is baked out of the plaster and molten metal – aluminum, bronze, stainless steel, zinc or other alloy – is poured in.

- Machining: Machining creates a part by removing material. The material may be rigid foam, metal, plastic or wood. Lathes, milling machines and grinders are all used in machining operations. This work is done by a machine shop.

- Metal Fabricating: Bending, cutting and folding of metal is performed a short-run job shop. The shop will also perform simple assembly operations.

- Plastic Fabricating: Sheets of plastic can be cut, bent and vacuum formed by plastic fabricators. Fabricators will also perform simple assembly operations.

- Sculpting: Old world techniques are alive and well. This is the best way to create ergonomic shapes.

- Computer Aided Prototyping:

- Laser Cutting: Cutting precise shapes from sheets of metal is done by laser cutting. 2D CAD (Computer Aided Design)drawings are necessary.

- Wire EDM (Electrical Discharge Machining): A block of steel can be cut in a precise shape via wire EDM. 2D CAD(Computer Aided Design) drawings are necessary.

- Solid Modeling: Solid modeling uses 3D CAD to create a virtual prototype that can be viewed on a computer screen from any angle, including from inside out. The 3D CAD file created for solid modeling can be used to generate an actual part you can hold in your hands via rapid prototyping.

- Photorealistic Modeling: If you want to imaginewhat a final product would look like then you'll use photorealistic modeling to create a photographic quality skin for your design.

- Rapid Prototyping aka 3D Printing: While rapid prototyping technologies differ greatly, all of them require a 3D CAD file to create a 3D part. Read intro to 3D printing here.

- Stereolithography (SLA): Amodel is created one layer at a time as a laser beam moves across a bath of liquid resin. The laser's movements are guided by a 3D CAD program. SLA enables a model to be made with high resolution because each layer can be very thin. This means that handwork to finish the part is less than with other rapid prototyping technologies. SLA parts are not used directly as working prototypes because SLA resins are relatively brittle and weak. To make a working prototype a silicone mold is made from the SLA model and then plastic or metal copies (investment casting) are produced.

- Selective Laser Sintering (SLS): Instead of using liquid resin SLS uses powdered material - plastics, ceramics, waxes and certain metals – to create a prototype part.After the laser beam melts one layer of powder the residual powder is removed and a fresh layer is spread to create the next layer. Layer after layer is fused, one on top of the other. A prototype part created with SLS can be made stronger since materials closer to actual production materials can be used. If made of wax (or ceramic) an SLS part could be used directly for investment casting; if made of metal it could be used as a mold to create multiple plastic or wax parts.

- Laminated Object Manufacturing (LOM): LOM uses sheets of material rather than resin or powder. The material, called "foil", could be plastic, paper or metal. Once the laser cuts a sheet another sheet is laid on top and bonded to the previously cut sheet.

- Direct Shell Production Casting (DSPC): Soligen's unique and proprietary DSPC prototyping method creates a ceramic mold for cast metal parts. Ceramic powder is "printed" and bonded one layer at a time.

What is a final prototype and how do I make one?

A final prototype or manufacturing prototype is a replica of the product that will be introduced to the market. The final prototype may use different materials and be made with different machines and processes, but it looks and functions exactly like a production unit. It conforms to drawings that will be used to manufacture the product in mass quantities. A primary reason to create a final prototype is to insure that all of the parts fit together as planned prior to finalizing production tooling.

A last step prior to full-scale production is called pilot production. This step may also be called prototype manufacturing. Products made in pilot production may be used for extensive field testing. Pilot production uses short run manufacturing technologies and assembly methods.

The additional expense of refining the design for manufacturing and commercial appeal can be substantial. However, the investment in professional engineering and product design is well worth it. Cost savings from a properly designed product are significant and manufacturers will not tell you how to design your product for lowest cost manufacturing (read the chapter on manufacturing to learn more about this). Industrial design gives a product shelf appeal and can mean commercial success or failure. The right time to hire a manufacturing engineer and an industrial designer is prior to committing to a final design.

If you plan to license your invention then you will probably never create a final prototype. In some ways you benefit by creating a prototype that is somewhat crude and that cannot be mistaken for a final product. Most companies have a "look" that they like to achieve for their products and will want your invention to conform to that look. Also, the expectations for a prototype are not as high as for a final product – with a prototype you can explain away problems that would be unacceptable in a final product.

Other Resources

3D Hubs - 3D Hubs is a great place to begin your search for 3D printing companies. You'll can find sources all over the world offering a wide range of services and technologies. Prices vary tremendously depending own the type of print you need - a function of quality and material. You'll need a 3D model file to send out for quotation.

Supplies for Invention Prototypes

McMaster-Carr - If it's available anywhere, McMaster-Carr probably has it in stock. Fantastic service and an outrageously broad selection of materials, parts and products... modeling clay, gears, chain drives, sheet plastic, grease, electric motors, pumps, tools of all kinds and much, much more.

MacRae's Blue Book - Find components and service providers.

ThomasNet.com - Find nearly any component that you might need to build a prototype. Lists of local service providers.

share this article: facebook

New Prototype

I was talking to some buddies of mine who helped design the prototype for lock washers. It's pretty cool stuff, and super interesting how prototypes are designed, and then finally come to fruition into a product.

by: Gary Neal

But do you need a prototype?

great list of prototype building resources! but a lot of people overlook the first step of understanding whether you need a prototype and what you are looking to achieve with it. different intentions will lead to different types of prototypes. Also don't under estimate your ability to create a prototype yourself, or with the help of local tradesman. In many cases, this would be enough. Check out Invention prototype, http://www.inventions-handbook.com/invention-prototype.html

by: Lisa

CPG(close power Generator)

i have invented an incredible Generator which proposed name is CPG(closed power Generator) CPG is fuel free Generator, it can produce complete free and environment friendly energy moreover the source is being used in CPG entirely different from all the existent energy source in the world. i have constructed a prototype now i iam upgrading CPG i am quite optimistic that the CPG would be a real alternative energy source in future. i want to sell my invention.

by: Syed Naveed Hussain Shah

don't get it

I don't get it, what's your point?

by: andrew johnson

prototype manufacturer

we are a prototype manufacturer in china,such as CNC plastic and metal prototype,metal sheet prototype,SLS/SLA prototype,turning,milling,design service. With good quality and fast delivery time 3-5days. If any one need help,pls feel free to contact me.

by: tina

can i trust them not to take my idea

I have 3 things I want proto types for, how do I know they will not dump it and then come back and make it them self?

by: Tom

Good

Exhaustive information on the subject. Thanks.

by: Saurabh

Great info here

Thanks for sharing the resources. Some of them I haven't seen before. i will try some out before the next time I'm prototyping something. Thanks!

by: Julian

To: Tom

They can't take your idea if it is patented. If they want to benefit from your product then who ever you are presenting it to has to accept it as your idea.

by: Malik

Need a Prototype or Engineering Services?

Check out Talos X (www.talosx.com). They are an engineering services company that works closely with entrepreneurs and start-ups to help build prototypes and IP strategies. Best group of guys that I have ever worked with... very personable and accommodating too!

by: TechGuru12

Sitting on the proto-type sideline.

As an artist and a tinkerer, I have had many great ideas in my life and like many others, have thought I was sitting on a goldmine. While sitting on the sidelines "thinking" of these great ideas other people eventually brought these ideas to life and some are still selling very strongly. Most have been products for targeted industries. Now that I'm actually taking a few of my newer ideas to the proto-typing stage I am finding it extremely difficult to even spend money with some suppliers that all claim they work with people in the proto-typing area. Even trying to purchase something they already make and supply such as a spring. I could use some existing products to build around a particular item and I find it almost impossible to get simple items like that. Very frustrating, short and rude suppliers offering no help at all even if I'm trying to spend money. Hopefully some of your leads here may change that. Good article.

by: Gregory Baker

Do you need a digital prototype for your invention?

If you're applying for a design patent or utility patent and you need to submit a prototype with your application, check out CotsisCAD.com. The experienced draftsmen at Cotsis will provide you with a firm price quote. No additional fees for rush jobs.

by: Peter Cotsis

Great

Very helpful for me, thank you

by: lin

Safety Rubber Safety Mat

I need a custom mat made of my safety invention. The manufacture that builds it will also manufacture it in large quanity's.

by: Lonnie Ingram

Safety Rubber Mat

Lonnie Ingram Get in touch with me regarding your specific production or prototype details. Will be happy to produce or refer you to company that can get the job done if outside my network of abilities. eholman@blackswansquared.com

by: Eddie Holman

Cosmetics Applicator Design and Prototype

I need an engineer to help design a prototype for a cosmetics application mechanism I have in mind. I need a computer model of what the unit will look like, how it will function internally and externally (the mechanics of it) and the overall design. Thank you

by: Jason Castellucci

Need help building a prototype I have an patent on

I am in need of help creating the prototype of the product I created in which I am looking forward to getting on Shark tank.

by: Danen

proto type job work

i need a work in design and prototype sheet metal work more than 15 year experience in press tool jigs & fixture and prototype work please send any inquiry sadguru equipments pvt.ltd bhosari pune (india)

by: nandkumar nikalje